The Darwin Motion Matrix 500 drive provides the Compact combination of power, ease of use, flexibility, and performance, Vector & Closed Loop Application

If you are looking to buy an inverter drive, Variable Frequency Drive, VFD, AC Drive, Variable Speed Drive, adjustable speed drive, or adjustable frequency drive? You can check out Darwin Motion catalogue and talk to our specialists

VFDs are used in different applications across commercial and industrial sectors. From small devices and heating to ventilation and cooling (HVAC) systems VFDs are used in variety of applications across industries such as mines, cranes, schools to office buildings.

There are different VFDs variable frequency drives available in the market for a unique application. However, while making a choice, user must consider several important factors:

Darwin Motion Matrix 500 is a variable frequency drive that has several features that make it a popular choice for industrial applications.

HERE ARE SOME OF THE TOP 20 FEATURES OF THE DARWIN MOTION MATRIX 500

| Item | Specification and Technical Data | |

| Main power connection | ||

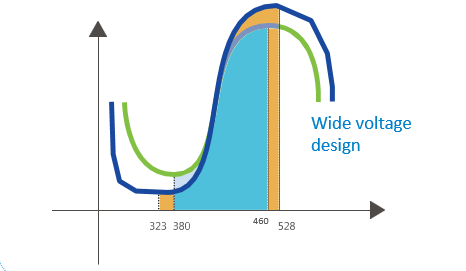

| Input voltage U1 | 220V/380V/500/690V±15% ;signal/three-phase power | |

| Input frequency f1 | 50...60Hz ±5Hz | |

| Output voltage U2 | 0...U1 (V)(The maximum output voltage equals the input power voltage.) | |

| Output frequency f2 | 0-1000Hz | |

| Carrier frequency | 2-8 KHz (The device can intelligently and automatically make optimal adjustment according to load characteristics and drive temperature.) | |

| Input voltage unbalance degree | Maximum: ±3% of rated inter-phase input voltage | |

| Efficiency | ≈ 98% (when operating at rated power) | Basic functions |

| Speed range | 0-1000Hz ( 0~30000 rpm, 60000rpm is optional ) | |

| Resolution of given speed | Digital setting: 1RPM Analog setting: 0.025% of maximum RPM | |

| Control mode | SVC control / FVC vector control | |

| Starting Speed | 200% @ 0.25Hz@ SVC control 200% @0Hz@ FVC control | |

| Speed ratio | 1 : 200 @ SVC control 1 : 3000 @ FVC control | |

| Steady-speed precision | ±0.5% @ SVC control ±0.01% @ FVC control | |

| Overload capacity | Heavy load application: 60s at 150% rated current @40°C. The time depends on the drive temperature under other conditions. General application: 60s at 120% rated current @40°C. The time depends on the drivetemperature under other conditions. | |

| Torque boost | Automatic torque boost. Manual torque boost 0.1%-30% | |

| Acceleration and deceleration curves | straight-line or S-curve acceleration and deceleration mode Two acceleration time values. The acceleration and deceleration time range : 0.0s-650.00s | |

| Simple PLCfunction | Achieve operationof up-to-16-stages speed(via built-in PLC or control terminals) | |

| Built-in PID | Conveniently achieve the process control close-loop control system | |

| Automatic voltage regulation (AVR) | When the grid voltage changes, the device automatically maintainsconstant output voltage. | |

| Overvoltage and overcurrent stall control | The current and voltage are automatically limited during running to avoid jump faults due to frequent overcurrent and overvoltage | Enhancements |

| Torque limiting and control | The torque is automatically limited operating (to avoid frequent overcurrent jumping fault due to too large torque). | |

| Protection function | Output shortcircuit protection, input & output phase loss protection, overcurrent protection, overvoltage protection,undervoltage protection, overheat protection, overload protection, brake chopper overload protection, brake chopper shortcircuit protection, brake resistor overload protection | |

| Non-stop during transient interruption | Keep the frequency converteroperating in a short time (by reducing feedback energy compensation voltageat the moment | |

| Model Code | Rated Value | General Load Application | Heavy Load Application | Noise Level | Heat Radiation | Air Volume | Dimension | ||||

In(A) | Imax(A) | ILd(A) | PLd(kW) | IHd(A) | PHd(kW) | dBA | W | M3/h | |||

4.8 | 6 | 4.5 | 0.75 | 2.5 | 0.37 | 45 | 40 | 53 | F1 | ||

7.5 | 10 | 7 | 1.5 | 4.5 | 0.75 | 45 | 94 | 53 | |||

11 | 15 | 10 | 2.2 | 7 | 1.5 | 45 | 172 | 53 | |||

15 | 20 | - | - | 10 | 2.2 | 45 | 232 | 53 | |||

| Model Code | Rated Value | General Load Application | Heavy Load Application | Noise Level | Heat Radiation | Air Volume | Dimension | ||||

In(A) | Imax(A) | ILd(A) | PLd(kW) | IHd(A) | PHd(kW) | dBA | W | M3/h | |||

5.2 | 7 | 5 | 1.5 | 2.5 | 0.75 | 45 | 40 | 53 | F1 | ||

6.3 | 9 | 6 | 2.2 | 4.2 | 1.5 | 45 | 76 | 53 | |||

10.5 | 15 | 9.8 | 4 | 5.6 | 2.2 | 45 | 97 | 53 | |||

14 | 20 | 13.5 | 5.5 | 10.5 | 4 | 45 | 172 | 53 | |||

18.2 | 25 | 17.5 | 7.5 | 14.5 | 5.5 | 45 | 210 | 53 | |||

26 | 36 | 25 | 11 | 17.6 | 7.5 | 45 | 325 | 55 | F2 | ||

28 | 35 | 26 | 15 | 25 | 11 | 45 | 420 | 55 | |||

41 | 57 | 38.6 | 18.5 | 35 | 15 | 57 | 550 | 145 | F3 | ||

48 | 67 | 46 | 22 | 41 | 18.5 | 57 | 660 | 145 | |||

63.5 | 89 | 61 | 30 | 48 | 22 | 57 | 890 | 145 | |||

78 | 109 | 75 | 37 | 66 | 30 | 60 | 1114 | 290 | F4 | ||

95 | 133 | 91 | 45 | 79 | 37 | 60 | 1140 | 290 | |||

120 | 168 | 115 | 55 | 94 | 45 | 60 | 1200 | 290 | |||

162 | 227 | 155 | 75 | 116 | 55 | 60 | 1440 | 350 | F5 | ||

185 | 222 | 178 | 90 | 160 | 75 | 60 | 1940 | 350 | |||

225 | 270 | 215 | 110 | 179 | 90 | 67 | 2200 | 570 | |||

| Model Code | Rated Value | General Load Application | Heavy Load Application | Noise Level | Heat Radiation | Air Volume | Dimension | ||||

In(A) | Imax(A) | ILd(A) | PLd(kW) | IHd(A) | PHd(kW) | dBA | W | M3/h | |||

272 | 326 | 261 | 132 | 215 | 110 | 68 | 3300 | 685 | F6 | ||

320 | 384 | 310 | 160 | 259 | 132 | 68 | 3850 | 685 | |||

375 | 450 | 360 | 200 | 314 | 160 | 68 | 4100 | 720 | F7 | ||

450 | 540 | 430 | 220 | 387 | 200 | 68 | 4600 | 720 | |||

487 | 584 | 470 | 250 | 427 | 220 | 68 | 5100 | 720 | |||

546 | 628 | 525 | 280 | 481 | 250 | 68 | 5782 | 1200 | F8 | ||

624 | 718 | 600 | 315 | 550 | 280 | 68 | 6252 | 1200 | |||

686 | 789 | 660 | 355 | 616 | 315 | 68 | 7866 | 1200 | |||

760 | 874 | 730 | 400 | 671 | 355 | 68 | 9100 | 1300 | F9 | ||

865 | 995 | 830 | 450 | 759 | 400 | 68 | 9900 | 1300 | |||

950 | 1093 | 920 | 500 | 850 | 450 | 68 | 10500 | 1680 | |||

1100 | 1265 | 1080 | 560 | 950 | 500 | 68 | 11500 | 1680 | |||

1200 | 1380 | 1150 | 630 | 1060 | 560 | 68 | 12600 | 1680 | |||

| Model Code | Rated Value | General Load Application | Heavy Load Application | Noise Level | Heat Radiation | Air Volume | Dimension | ||||

In(A) | Imax(A) | ILd(A) | PLd(kW) | IHd(A) | PHd(kW) | dBA | W | M3/h | |||

22 | 44 | 21 | 18.5 | 18 | 15 | 57 | 550 | 290 | F4 | ||

26 | 54 | 25 | 22 | 22 | 18.5 | 57 | 660 | 290 | |||

35 | 64 | 33 | 30 | 27 | 22 | 57 | 890 | 290 | |||

44 | 70 | 41 | 37 | 35 | 30 | 60 | 1114 | 290 | |||

49 | 71 | 48 | 45 | 45 | 37 | 60 | 1140 | 290 | |||

61 | 104 | 58 | 55 | 52 | 45 | 60 | 1200 | 290 | |||

80 | 124 | 80 | 75 | 65 | 55 | 60 | 1440 | 290 | |||

98 | 168 | 93 | 90 | 86 | 75 | 60 | 1940 | 350 | F5 | ||

119 | 198 | 113 | 110 | 100 | 90 | 67 | 2200 | 350 | |||

142 | 200 | 142 | 132 | 121 | 110 | 68 | 3300 | 350 | |||

175 | 220 | 165 | 160 | 150 | 132 | 68 | 3850 | 350 | |||

220 | 240 | 215 | 200 | 175 | 160 | 68 | 4100 | 720 | F6 | ||

271 | 320 | 245 | 220 | 220 | 200 | 68 | 4600 | 720 | |||

290 | 350 | 265 | 250 | 250 | 220 | 68 | 5100 | 720 | |||

300 | 360 | 295 | 280 | 270 | 250 | 68 | 5782 | 1000 | F7 | ||

330 | 360 | 325 | 315 | 300 | 280 | 68 | 3252 | 1000 | |||

370 | 480 | 360 | 355 | 330 | 315 | 68 | 7866 | 1000 | |||

| Model Code | Rated Value | General Load Application | Heavy Load Application | Noise Level | Heat Radiation | Air Volume | Dimension | ||||

In(A) | Imax(A) | ILd(A) | PLd(kW) | IHd(A) | PHd(kW) | dBA | W | M3/h | |||

430 | 520 | 420 | 400 | 385 | 355 | 68 | 9100 | 1300 | F82 | ||

470 | 655 | 455 | 450 | 430 | 400 | 65 | 9900 | 1300 | |||

522 | 700 | 505 | 500 | 470 | 450 | 68 | 10500 | 1300 | |||

590 | 800 | 571 | 560 | 555 | 500 | 68 | 11500 | 1300 | |||

721 | 820 | 710 | 630 | 600 | 560 | 68 | 12600 | 1300 | |||

900 | 1350 | 880 | 800 | 680 | 630 | 68 | 16000 | 1680 | F92 | ||

1160 | 1750 | 1115 | 1100 | 900 | 800 | 68 | 20000 | 1680 | F104 | ||

1250 | 2000 | 1250 | 1250 | 1114 | 1100 | 68 | 26000 | 1680 | |||

1350 | 2200 | 1400 | 1400 | 1250 | 1250 | 68 | 32000 | 1680 | |||

| Name | Country/Language | Download | File Type |

| Technical Catalogue | English | ||

| Technical Specification | English |